Home » Acoustical Underlayment (old) » Examples of Application » Laying on Existing Ceramic Flooring With New Thin Underfloor Heating

In an old building, a new thin-layer underfloor heating with screed is to be laid on a existing ceramic covering. The old pavement has sufficient load-bearing capacity and adhesion to the subsoil. The stresses resulting from the thermal load on the structure are absorbed by the decoupling mat. As a result, no stresses are transferred to the ceramic covering. The mat also supports heat transport.

Silicone sealant

Flex joint

Lightweight flex adhesive mortar

Decoupling, crack-bridging fleece

Lightweight flex adhesive mortar

Fiber-reinforced leveling compound

Thin-layer floor heating system

Dispersion primer

Edge insulation strips

Substrate – existing ceramic covering

We would welcome the opportunity to speak with you about your unique needs.

Polysols

851 Simuel Rd

Spartanburg, SC 29301

Our seam tape boasts unparalleled strength, providing a reliable and resilient bond for artificial turf seams. This strength ensures that your turf surface remains intact and flawless, even under heavy foot traffic and varying weather conditions.

Whether you’re working on a residential lawn, a sports field, or a commercial landscape, our Artificial Turf Seam Tape is versatile enough to meet the demands of various applications. It adapts seamlessly to different turf types and installation scenarios.

Our seam tape, when paired with our heavy-duty turf glue, forms an unparalleled combination that delivers an ultimate bonding power. Engineered to synergize seamlessly, these products create a bond that surpasses industry standards, ensuring an exceptionally durable connection between the seam tape and the turf. The emphasis is on the synergy between the products, resulting in a bond that stands up to the demands of heavy traffic, environmental challenges, and the test of time.

We prioritize quality in every aspect of our products. The artificial turf seam tape is constructed from premium nonwoven material, known for its durability and resistance to wear and tear. This ensures that our seam tape not only performs exceptionally well but also maintains its integrity over time.

Our seam tape boasts unparalleled strength, providing a reliable and resilient bond for artificial turf seams. This strength ensures that your turf surface remains intact and flawless, even under heavy foot traffic and varying weather conditions.

The Sound Silent 7 decoupling boards were tested without bonding the boards to the subfloor. In addition to its light to moderate commercial usage, the boards, when installed without bonding, can save projects over 33% in installation and material costs. Our boards when installed without bonding to the subfloor has a 4-step installation process compared to rubber membranes which typically have 8 steps of installation on average.

This reduction of installation steps allows for your labor cost to be cut in half when installing on a job and you do not need nearly the amount of materials that are typical when installing rubber membranes. Our installation method allows for a third of the cost to be eliminated.

The Sound Silent 7 decoupling boards, are designed and formed into hardened, rigid, boards. Because of this effective design, our boards are the perfect way to help close gaps left behind when replacing old floor coverings. Because they are rigid and support any floor covering you can utilize the boards to help build that space back up to a level sub-floor and continue having a smooth flowing floor all throughout your space.

Crack isolation is an important consideration when it comes to installing tile or other hard surface flooring, as cracks can cause damage to the flooring and potentially compromise its integrity. One method for crack isolation is the use of sound isolation systems, such as the Sound Silent 7 decoupling boards.

The Sound Silent 7 decoupling boards are designed to provide a separation layer between the subfloor and the finished flooring, helping to absorb any movement or impact that may occur. This helps to reduce the likelihood of cracks forming in the finished flooring due to the subfloor shifting or settling.

The Sound Silent 7 decoupling boards are also designed to be able to support cracks over 1/8 of an inch. This is important because even with the best crack prevention measures in place, some degree of cracking can still occur over time as a result of natural settling or movement in the subfloor.

The ability of Silent 7 decoupling boards to support cracks over 1/8 of an inch means that they can help to ensure that the finished flooring remains structurally sound, even in the presence of some cracking. This can be particularly important in high-traffic areas or in areas where heavy loads or equipment may be placed on the flooring.

Sound Silent 7 decoupling boards are a sustainable solution for noise reduction in construction projects. One of the key features of Sound Silent 7 decoupling boards is that they are made from 100% recycled non-woven material. This means that the material used in the boards has been repurposed from previously used materials, rather than relying on new materials that would have otherwise been discarded.

The use of recycled non-woven material in Sound Silent 7 decoupling boards provides several environmental benefits. Firstly, it reduces the amount of waste that ends up in landfills, which can help to reduce the carbon footprint of construction projects. Secondly, it reduces the need for new materials to be manufactured, which can help to conserve natural resources and reduce the energy required for production.

High impact sound absorption underlayment is a type of material that is designed to reduce noise transmission in floors. It is typically installed beneath a layer of flooring material, such as hardwood, laminate, or tile, to dampen the sound of footsteps and other impacts. The underlayment works by absorbing the energy from impact and converting it into a minimal amount of sound, which results in a quieter living or working space. This can be particularly useful in multi-story buildings, where sound transmission can be a major problem for residents or workers.

Property Managers, designers, and architects alike have to be knowledgeable about an extensive amount of issues to do with building systems and materials. Combine that with the challenging personalities one would have to deal with, and this industry can chew you up and spit you out whole. It’s especially difficult when you are dealing in an area where there is so much misinformation. The ‘Sound Control Underlayment market is one of those places where wild performance claims abound, yet solid testing information is rarely backing up the claims that the testing suggests. So, what is a person to do? Question everything! The purpose of this blog is to help people understand the sound control industry for flooring and to ask the right questions and gather the information required to make an educated decision about Sound Control Underlayment. It’s vital that any designer, architect, or property manager, not only protect their reputation but also demonstrate due diligence and potentially shield them from legal issues that may arise due to insufficient knowledge.

Sound Control Underlayment is being specified in condominiums and multifamily dwellings to keep the peace and allow the serenity of each resident’s suite. They must, when new, perform according to product claims; they also must not cause issues in the future. So where do you start? Well, it is imperative to ask the right questions:

They seem like pretty simple questions, right? They are not! Many manufacturers of underlayment are betting on you not being an Acoustical Engineer and hope you will scan the sales literature for the highest Impact Insulation Class (IIC) rating, approve it, and get on with your day. Millions of square feet of sub-standard underlayment have been installed, leaving desperate residents, animosity towards neighbors, frustrated tenants, and management boards with ‘no win’ legal situations. Let’s look at each of those questions to understand what they truly mean.

The first red flag is product literature or packaging that shows an IIC rating but does not indicate the building assembly that it was tested on. This is by far the most common ruse. The producer of the literature is banking on keeping the PM or the general public in the dark about what IIC means. Higher is better right? This is where the field runs from truthful to deliberately misleading. If the indicated IIC ratings are in the high 60s or 70s and do not show the testing assembly – RUN! But what does IIC mean and how can you understand and apply this rating? IIC is Impact Insulation Class. Predominantly it means how well an underlayment reduces the sound of a footfall, furniture drag, spoon fall, etc.

What is a reasonable requirement for the financial demographics of your building?

What will happen as this product ages? Will it harden, crush, dry out, absorb, or wick?

The most popular of underlayment currently. This is the material that has been grandfathered forever, because it’s been around forever. On a 6” concrete slab with a wood floor and 5 mm cork you’ll get approximately a 50 IIC. On an 8” slab it could get up to 55 IIC. Cork is kind of a known commodity but has some downstream issues that should be considered. Cork is, as we know, bark off a tree. Let’s look at a product we all know and love for an example of its performance – wine! Wine corks are top quality because they protect precious cargo. Now, mentally pull the cork out of your favourite two-year-old bottle. The end of the cork that was next to the wine is still soft and pliable. What’s the other end like? It’s compressed, hard, dry and showing signs of getting flaky. That’s because it was exposed to the air. The same happens with the thin layer of cork under flooring. It dries, gets harder and flakes out – along with it goes the acoustic properties we needed to begin with

Foam does a reasonable job of taking up any minor irregularities in the subfloor and they do take away some of the ‘clacky’ sound laminate can have as you walk on it. When foam is new and ‘fluffy’ it exhibits some reasonable sound control properties. But there’s a problem. The problem is foam cannot withstand ongoing loads. It eventually crushes out and along with that physical deformation goes the sound control properties that we need. Many foam products available today are re-purposed packaging material; foam gained a foothold on the underlayment market because it’s cheap. But you get what you pay for in the sound control department here. Here’s a really easy test any project manager can do. Take any underlayment and put it under the corner of your desk or a chair leg for a few days. Then take it out, let it recover for a few minutes then look at it and feel it. Did it permanently deform? It will do the same over time under the flooring in that suite

Rubber underlayment is becoming the new Granddaddy on the market. In Europe and North America, it is being made by companies that used to manufacture cork. Rubber exhibits superior sound control properties, strength and aging characteristics that make it particularly suitable for sound control underlayment. Made from strong, recycled tires, rubber cannot be crushed out. This underlayment can be grossly overloaded but recover completely when the load is removed. It is timeless in that they will never have to be replaced in the lifetime of the building. However, rubber does not add any additional strength properties to the flooring assembly. Also, a major concern with rubber is that it releases harmful toxins over time. Some of these chemicals appear on the Office of Environment Health Hazard Assessment’s (OEHHA) Reference Exposure Lists

Felt underlayment exhibits good sound control properties and generally good aging characteristics. It does a great job with sound control, but again there are downstream issues that could become a big problem. A wood or laminate floor is actually a collection of pieces with spaces in between that narrow and widen with the seasons as the materials react to the humidity levels. This is natural. While felt exhibits good sound control and support characteristics, it also allows liquid to ‘wick’ laterally under the flooring. Once this happens, the floor fails. What are the chances that a floor will experience a spill in its lifetime? Probably 100 percent. If a felted underlay is used and a spill occurs, resulting in floor failure, who’s responsible?

Here are the questions you need to come armed with when investigating any acoustic underlayment.

*Source hushcitysp.com

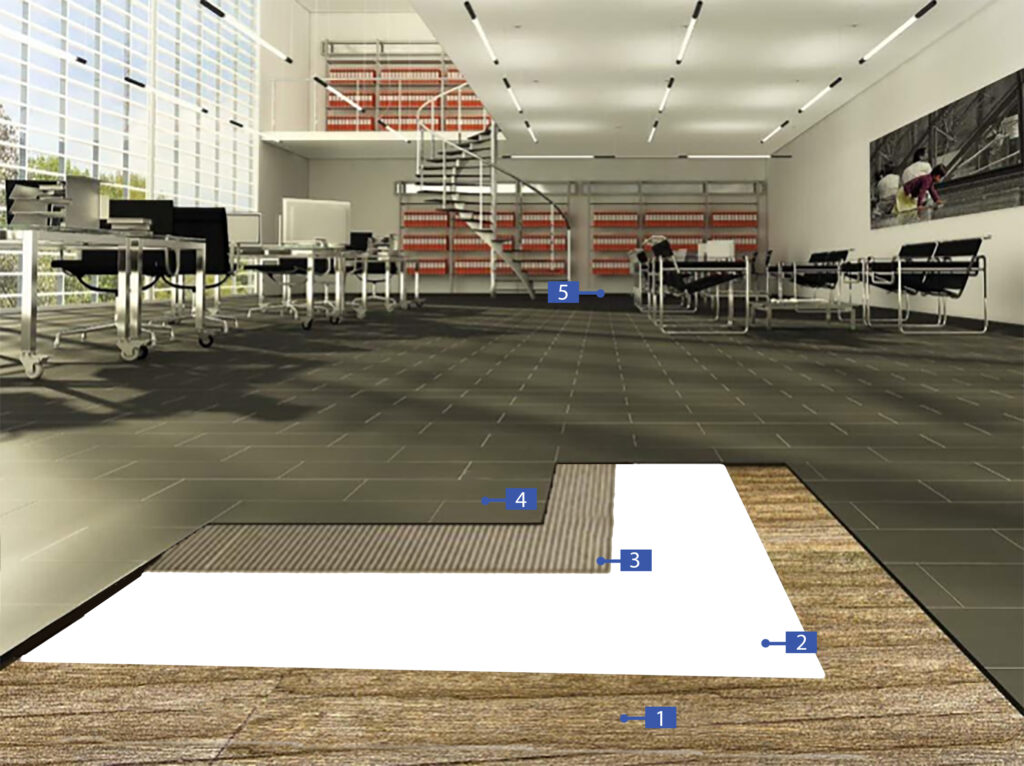

Due to their swelling and shrinkage behaviour, wooden planks are a critical installation substrate for rigid coverings made of ceramic plates and natural stones. Old wooden floors often have irregularities, that need to be leveled before laying ceramic or stone tiles. The wooden planks must be screwed to vibration-free, load-bearing wooden beam constructions (max. 40 cm beam spacing). Sufficient rear ventilation must be ensured. In order to lay a ceramic slab or a natural stone covering on wooden planks without damage, it must be decoupled from the substrate. As a positive side effect, this also improves impact sound.

1

Wooden Substrate

2

Sound Silent 7 decoupling boards

3

Mortar

4

Floor Covering (tile)

5

Grout and sealer

Due to the shrinkage process that takes place during the hydration and drying phase, concrete is subject to a reduction in volume. Therefore, on concretes younger than six months, rigid coverings should not be laid with conventional products. Otherwise, the resulting stresses can result in sustainable composite faults and pavement detachment if occupied too quickly. Depending on the age of the concrete, we recommend different, deformable adhesive mortar systems and/or decoupling, which can safely absorb any changes in shape from the substrate.

1

Concrete Substrate

2

Optional Primer (Per manufacturer’s guidelines)

3

Sound Silent 7 decoupling boards

4

Mortar

5

Floor Covering (tile)

6

Grout and sealer